Damn. Those are some clean ass layer lines.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

Yeah. For the speed it was printing at, for sure. I think it was a single wall as well.

I'm wondering, how are you dialing in customized, (in your case hot-end and extruder) printers with input shaping?

Is it something working for any device and any combination of parts, if the computational part supports it?

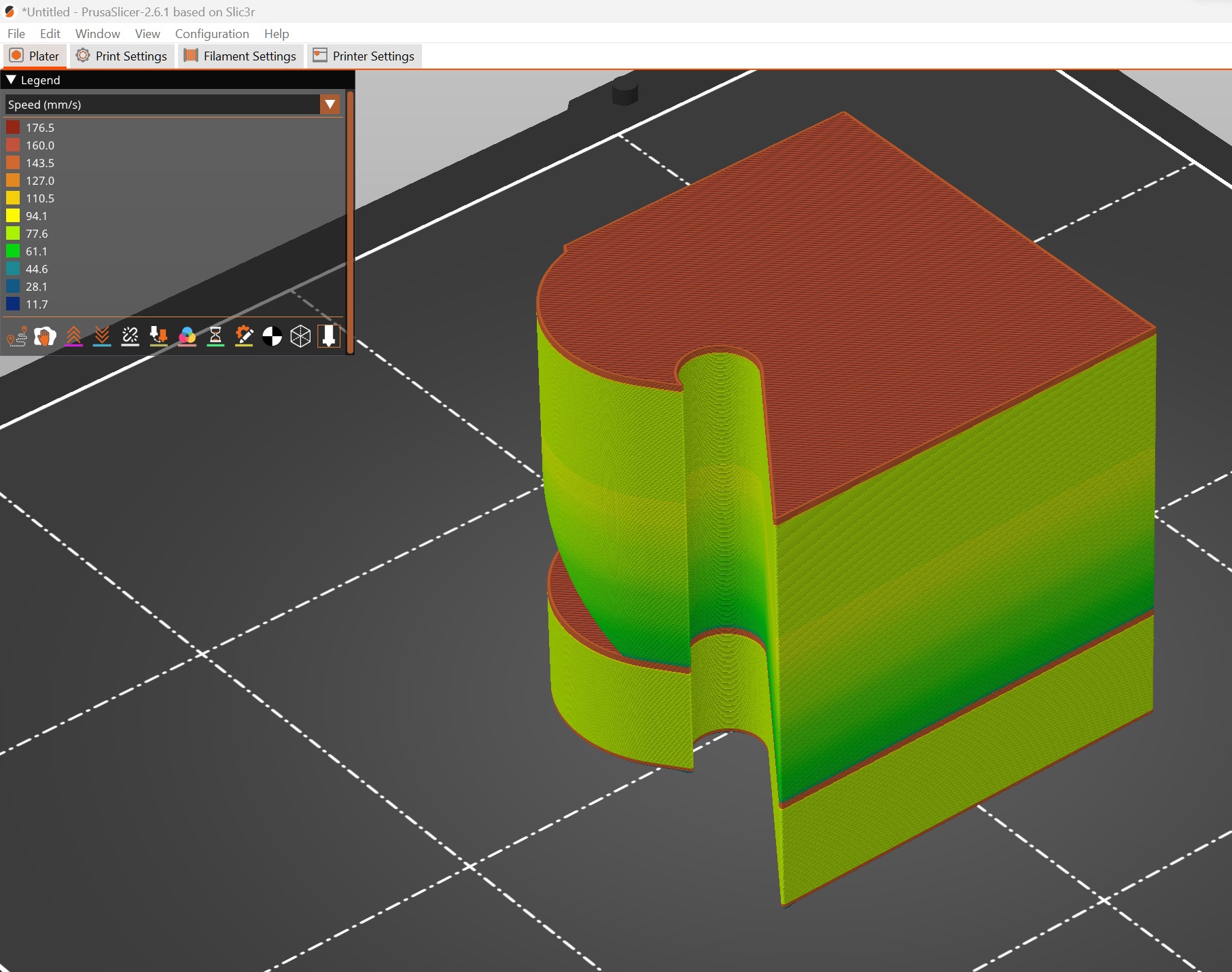

It's all factory settings in this case. I am running my own print now with the new Prusa Slicer 2.6.1 profile. So, nothing is dialed in yet. (Edit: I am using Voxel PLA Pro which can use the Prusament filament profiles.)

There are options to tweak the input shaping in the printer menu but I haven't played with them yet.

I find it very odd that the factory sliced gcode for the benchy even worked with my printer mods. The input shaping is supposed to be for the stock MINI, but it works fine for my printer. (That boggles my mind as that breaks how I think of mechanical resonance.)

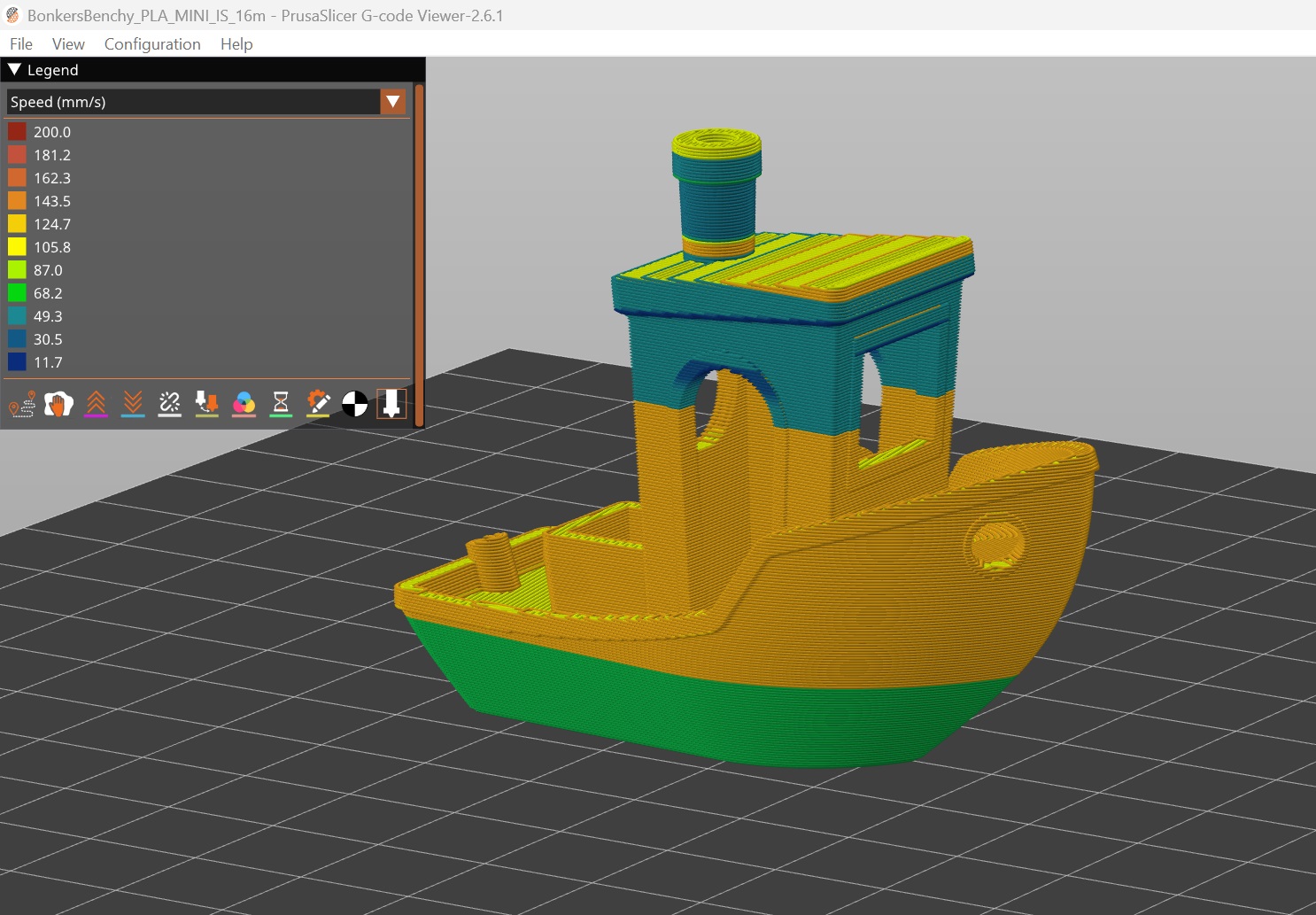

I installed and have been testing the new firmware with great results. I was a little disappointed that the bonkers benchy kind of cheated by using 5% infill, single exterior walls, and less top/bottom layers, but it was super satisfying watching the print head whip around. I need to refresh the bearings before I print too much else.

Yeah, it was a little bit of a hack, but it's just a benchy after all. You can mostly replicate those speeds, but not quite. Prusa mostly used three different static print speeds, with travel moves all being at max.

At least ya' can't say I didn't warn people about the bearing noise. It shook the hell of of mine. ;)

Add a reply to this comment if you want me to test a PLA print for you before you update your own printer.. (Try to keep it modest. I have lots of filament but don't want to tie up the printer for too long.)

Slicing examples: BonkerBenchy vs Prusa Slicer (400mm/s, all speeds) test: